Specialists in Automated Bagging & Palletising Systems

BAB 180S

Belt Feed Unit

Introducing the BAB-180S by Bulk Automation, a cutting-edge mid-range bulk bagger designed to revolutionize the bagging process with unparalleled efficiency and precision.

The BAB-180S boasts the ability to fill 2-3 bulk bags per minute, thanks to its 8m3/500-1200kg heavy-duty side loading hopper and durable rubber trough conveyor feed belt. Equipped with an electronic load cell bag frame and a precise weigh indicator, this system guarantees precise bagging results every time.

Operated through an integrated weighing system, the Bulk Bag Filling process fills the bag to a pre-set weight, ensuring that bulk automation is not only fast and accurate but also user-friendly. Perfect for tunnel or looped FIBC Bulk Bags, operators simply place the bags onto the waiting weigh frame, and the filling process commences. Once the desired weight is achieved, the feed belt halts, and the filled bag is ready for removal.

The BAB-180S can be tailored to accommodate a variety of products and customized to meet the unique specifications and needs of each customer. This customization guarantees that the unit surpasses expectations in terms of productivity and reliability.

FEATURES AND BENEFITS

BAGS & SIZES

DIMENSIONS

Minimum – 600 x 600 mm

Maximum – 1200 x 1500 mm

TYPES

Laminated Raffia, PP Material, Woven Raffia

MATERIALS

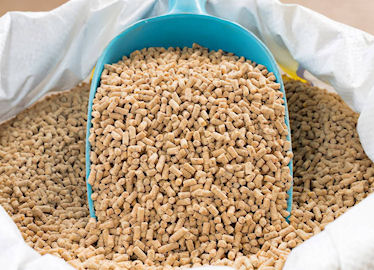

Aggregates, Wood pellets, Rock Salt, Animal Feed, Coal and more

SUITABLE PRODUCT TYPES & SECTORS