Specialists in Automated Bagging & Palletising Systems

BAB 120

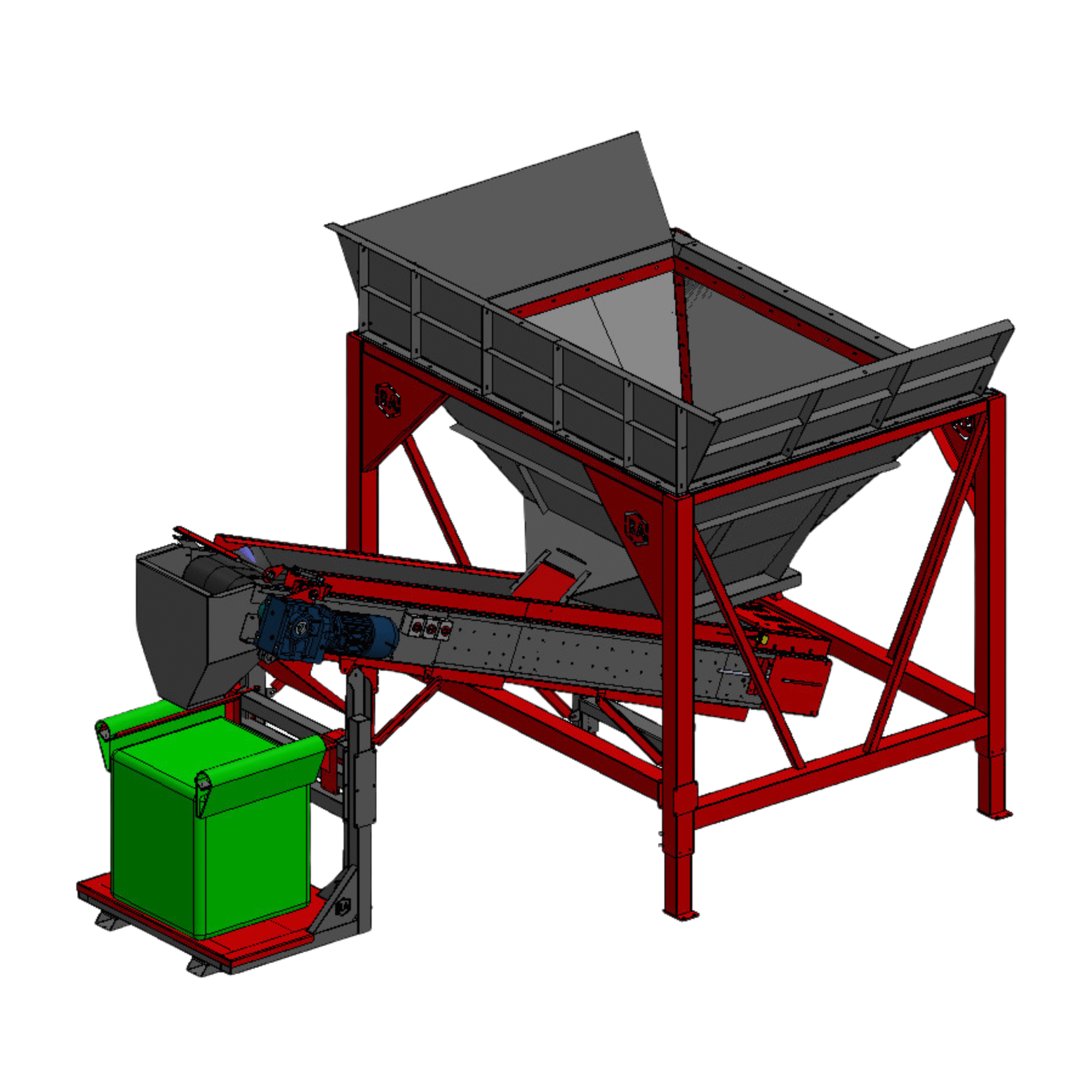

Belt Feed Unit

Introducing the BAB-120B – Bulk Bag Filling System, by Bulk Automation. This entry-level bulk bagger is designed to streamline the bagging process with efficiency and precision.

The BAB-120B is capable of filling 1-2 bulk bags per minute, thanks to its 4m3/500-1200kg heavy-duty hopper that feeds onto a durable rubber trough conveyor feed belt. Equipped with an electronic load cell bag frame and a precise weigh indicator, this system ensures accurate bagging every time.

Controlled via an integrated weighing system, the Bulk Bag Filling process fills the bag to a pre-set weight, making bulk automation quick, accurate, and user-friendly. Ideal for tunnel or looped FIBC Bulk Bags, operators simply place the bags onto the waiting weigh frame and the filling process begins. Once the target weight is reached, the feed belt stops, and the filled bag is ready to be removed.

The BAB-120B can be customized to accommodate various products and tailored to meet the unique specifications and requirements of each customer. This ensures that the unit exceeds expectations in terms of productivity and reliability.

FEATURES AND BENEFITS

BAGS & SIZES

DIMENSIONS

Minimum – 600 x 600 mm

Maximum – 1200 x 1500 mm

TYPES

Laminated Raffia, PP Material, Woven Raffia

MATERIALS

Aggregates, Wood pellets, Rock Salt, Animal Feed, Coal and more

SUITABLE PRODUCT TYPES & SECTORS